- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

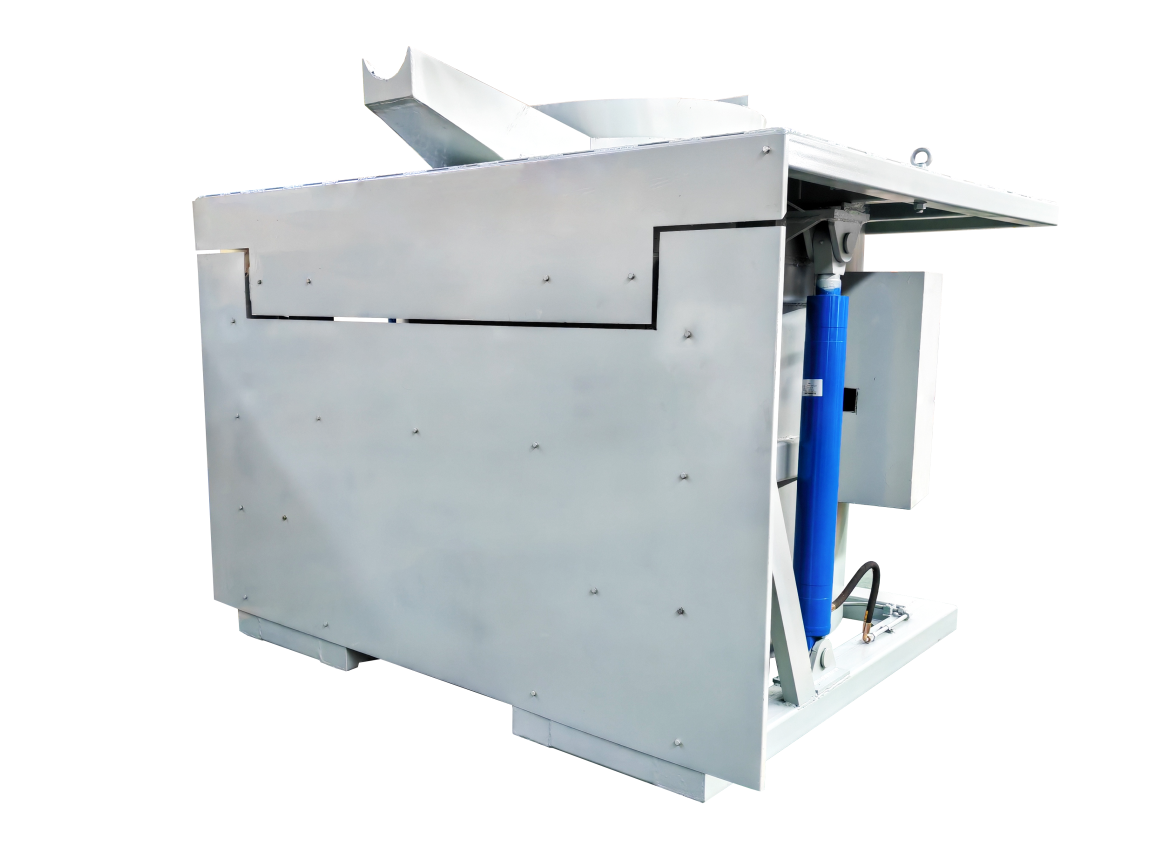

Application:

Smelting the low-melting-point metal; such as Aluminum, Zinc, Lead, Stannum, etc.

| Model | Working Capacity for Aluminum(kg) | Working Capacity for Zinc(kg) | Working Capacity for Magnesium(kg) | Working Capacity for Lead(kg) | Power(kw) | Rated Temperature(℃) | Voltage(v) | Melting Time(hour) | Crucible Size(Φ*hight mm) |

| RTM-3 | 3 | 8 | 2 | 13 | 3 | 950 | 380 | 2.5 | 120*150 |

| RTM-5 | 5 | 13 | 3 | 21 | 5 | 950 | 380 | 2.5 | 175*210 |

| RTM-10 | 10 | 26 | 6 | 42 | 7.5 | 950 | 380 | 2.5 | 210*250 |

| RTM-15 | 15 | 40 | 10 | 63 | 12 | 950 | 380 | 2.5 | 300*400 |

| RTM-20 | 20 | 53 | 13 | 84 | 15 | 950 | 380 | 2.5 | 330*370 |

| RTM-30 | 30 | 79 | 19 | 126 | 20 | 950 | 380 | 2.5 | 340*430 |

| RTM-50 | 50 | 132 | 32 | 210 | 25 | 950 | 380 | 2.5 | 380*500 |

| RTM-100 | 100 | 264 | 64 | 420 | 35 | 950 | 380 | 2.5 | 460*580 |

| RTM-150 | 150 | 397 | 97 | 630 | 45 | 950 | 380 | 2.5 | 530*530 |

| RTM-250 | 250 | 661 | 161 | 1050 | 45 | 950 | 380 | 2.5 | 615*630 |

| RTM-300 | 300 | 793 | 193 | 1260 | 60 | 950 | 380 | 2.5 | 615*700 |

| RTM-350 | 350 | 926 | 226 | 1471 | 75 | 950 | 380 | 3 | 715*700 |

| RTM-400 | 400 | 1058 | 258 | 1681 | 75 | 950 | 380 | 3 | 715*740 |

| RTM-500 | 500 | 1322 | 322 | 2101 | 90 | 950 | 380 | 3.5 | 775*750 |

| RTM-600 | 600 | 1587 | 387 | 2521 | 110 | 950 | 380 | 3.5 | 780*900 |

| RTM-800 | 800 | 2116 | 516 | 3361 | 130 | 950 | 380 | 3.5 | 880*900 |

| RTM-1000 | 1000 | 2644 | 644 | 4201 | 160 | 950 | 380 | 4 | 880*1000 |

| RTM-1200 | 1200 | 3173 | 773 | 5042 | 200 | 950 | 380 | 4 | 980*1080 |

The parallel power supply adjusts the power through the rectifier. The variable frequency power has lower technical requirements for components and the cost of components is lower. So, manufacturer can reduce the cost of production. After years of use and development, Parallel power supply has stable performance with favorable price, which is suitable for low investment and the initial stage of the user.

Spilt metal detection

Low metal temperature alarm

Thyristor power control

Low Energy Costs

Good Metal Temperature Control

Very Low Casing Temperature

Low Noise Level

Low Holding Costs

Simple Maintenance

CE marked

Don’t hesitate to fill in the form & we will reply to you as soon as possible!