- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

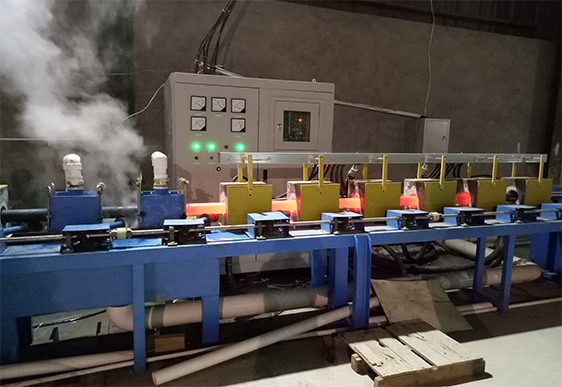

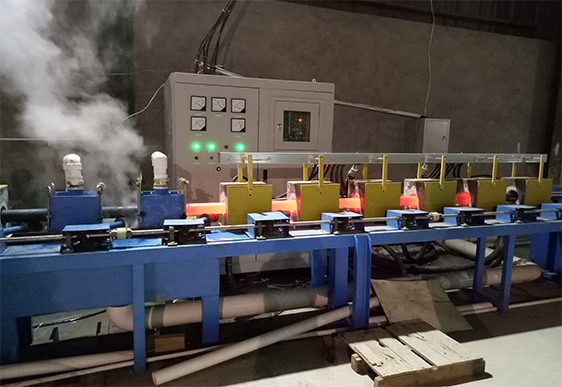

Application:

1. metal forging

2. metal quenching

3. metal reheating

4. other heat treatment field

1.Fast heating,low power consumption

2.Non-contact heating

3.Local heating

4.Uniform heating

5.High heating efficiency

6.Easy temperature control

Induction furnace is mainly used for melting carbon steel, alloy steel, special steel, also can be used for copper, aluminum and other non-ferrous metal smelting and heating.

1.Billet heating

2.Heat treatment

3.High temperature sintering

4.Heavy gear heating

The inductor is square, the inductor is wrapped by T2 copper tube, the external is covered by imported refractory material, with high strength, not easy to collapse characteristics. The whole structure is covered by insulation board, and both ends are sealed by purple copper plate to reduce the influence of magnetic leakage on the whole equipment.

There is space between the inductor turns to improve the efficiency of coil closure, so that the water vapor in the furnace lining can be better evaporated and the service life is longer.

PLC remote console using liquid crystal touch screen, the running status of equipment without interruption monitoring display, parameter display, parameter adjustment, mechanical part of the start off, PLC process setting, with humanized intelligent man-machine interface.

The control system integrates the intelligent temperature control function, and can adjust the heating temperature accurately with the infrared thermometer.

With water temperature alarm, water pressure alarm, phase alarm, leakage protection and other early warning systems.

This set of power control system by modular layout, structure optimization, maintenance more quickly.

The workpiece on the storage rack is rolled into the transmission system, and then into the heating system to start heating.

When the workpiece is heated, it reaches the automatic turnover system through the roller table and turns the heated workpiece into the material receiving rack.

Don’t hesitate to fill in the form & we will reply to you as soon as possible!