- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

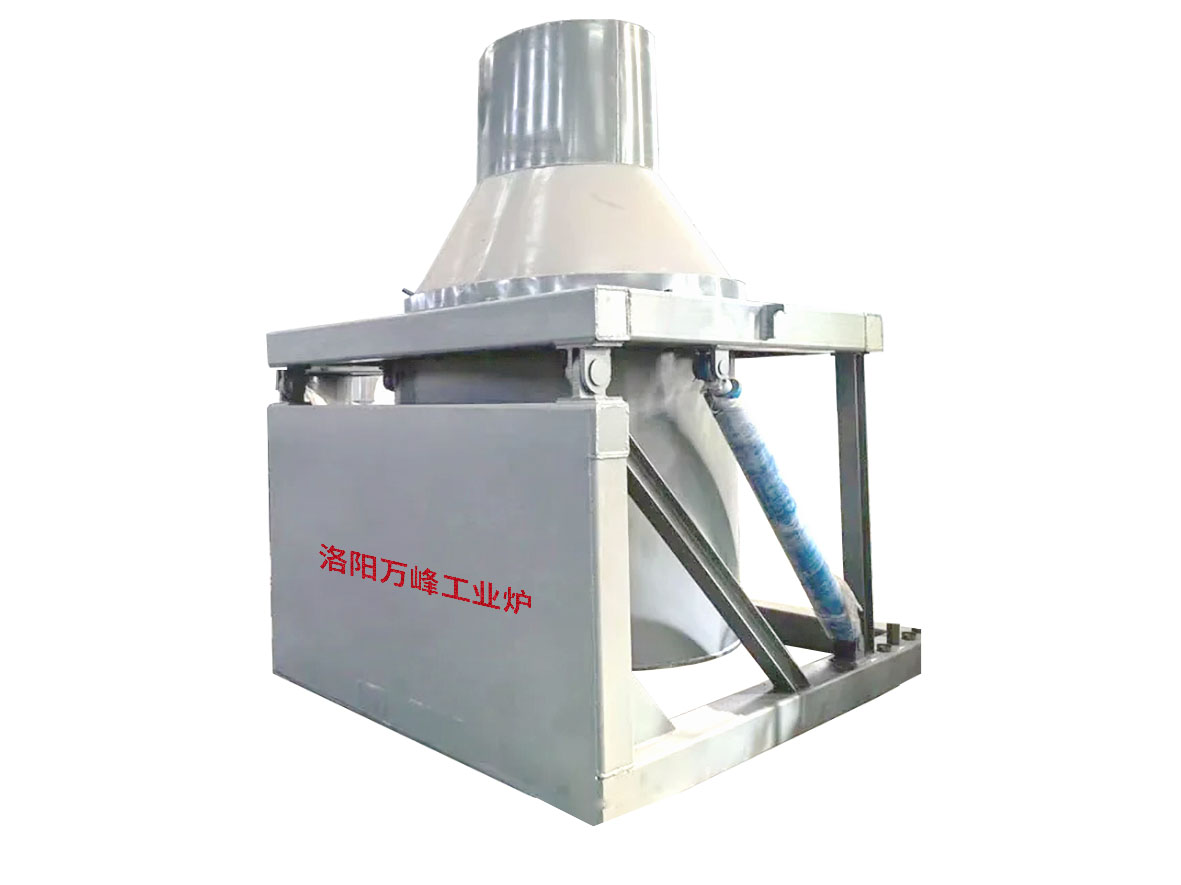

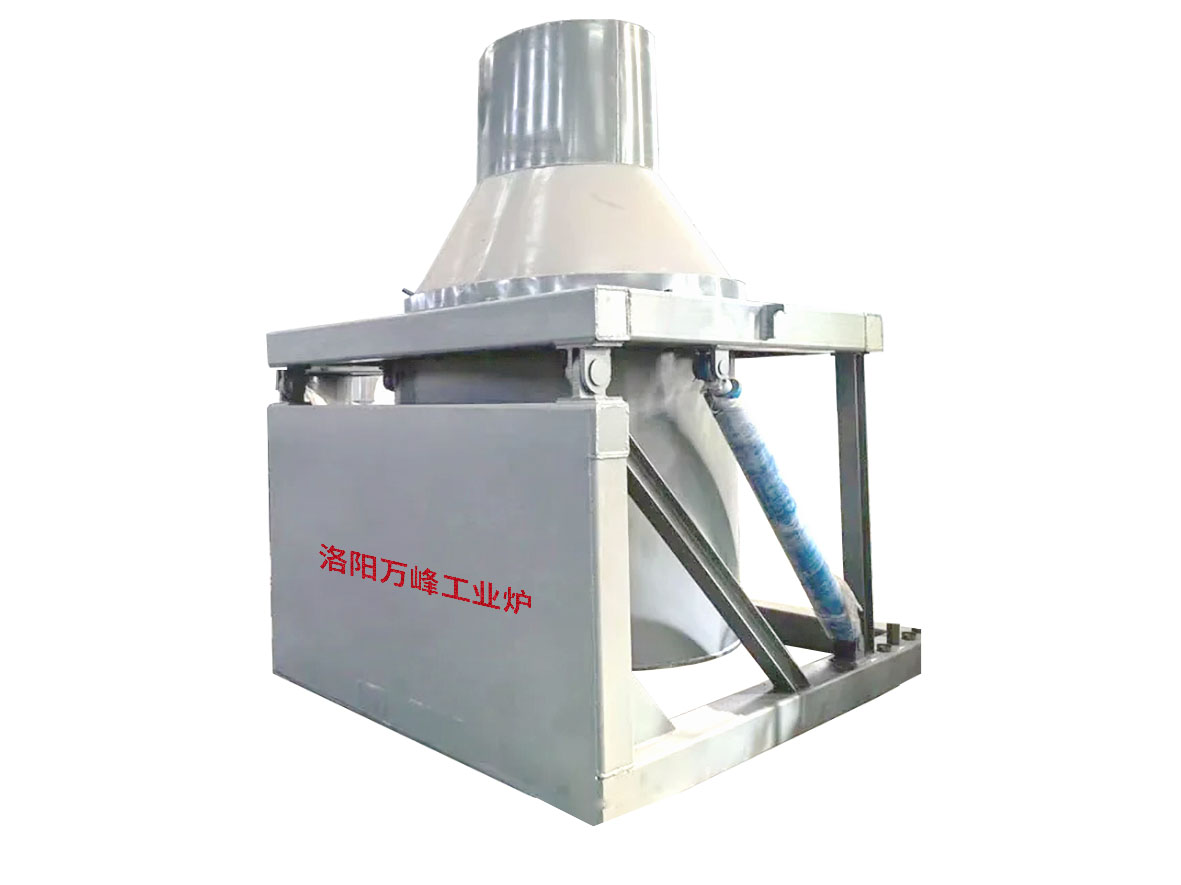

Product overview:

A vacuum distillation electric furnace utilizes electromagnetic phase change for heat exchange, and the heat released by magnetic energy is absorbed by the material. When the temperature reaches the saturation temperature under a certain vacuum state, it evaporates into saturation and steam, completing the first alternating transformation of solid phase change gas. The condenser and steam enter the evaporation chamber to continue absorbing heat and complete the gas-liquid alternating cycle. The lower structure of the vacuum distillation electric furnace consists of a combustion chamber and heat transfer components, while the upper part is a vacuum chamber with condensation and recovery components inserted. The vacuum chamber is connected to an exhaust unit to maintain a stable high vacuum degree. And extract the water vapor gas from the vacuum chamber. Improve the high purity of the product.

Don’t hesitate to fill in the form & we will reply to you as soon as possible!