- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

Application:

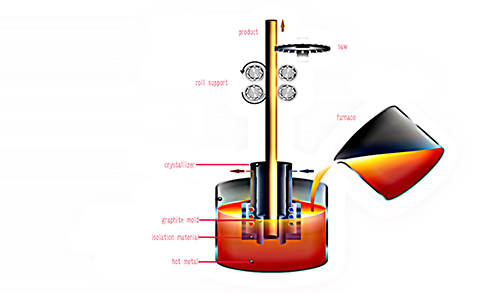

The upcasting continuous casting machine is the good solution for copper/brass/gold/silver, tube, sheet production with small investment. Our product is stable in furnace running and good drawability in casting.

| Item | Mid frequency furnace type | Line frequency furnace type |

| Output | 500kg-4000T | 2000T-12000T |

| furnace Body | equipment can start or stop at any time | equipment runs 24 h*7 |

| Melting/Casting Metal |

Low oxygen copper, oxygen-free copper |

|

| Casting way | Upcasting | |

| Power supply | Electric | |

| Power | Customized | |

| Mold | Crystallizer | |

| Strands | Customized | |

| Drawing Speed | 1.0-3.0m/min | |

| Available casting billet | Tube / Round bar / Strip | |

| Structure diagram |  |

|

Don’t hesitate to fill in the form & we will reply to you as soon as possible!