- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

Used for any recycled aluminum, waste aluminum, aluminum scrap, aluminum alloy or aluminum metal obtained by re-melting and refining waste aluminum and aluminum alloy materials, copper, zinc and lead scrap and other metal.

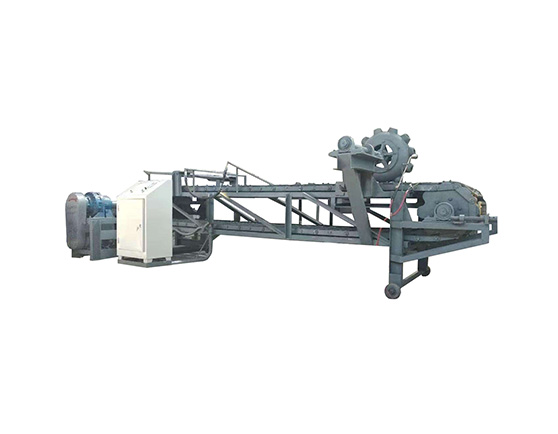

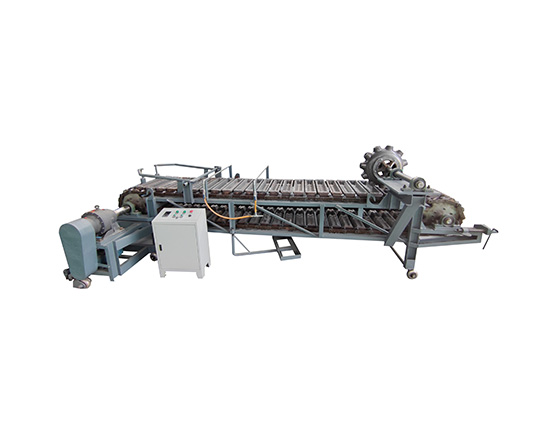

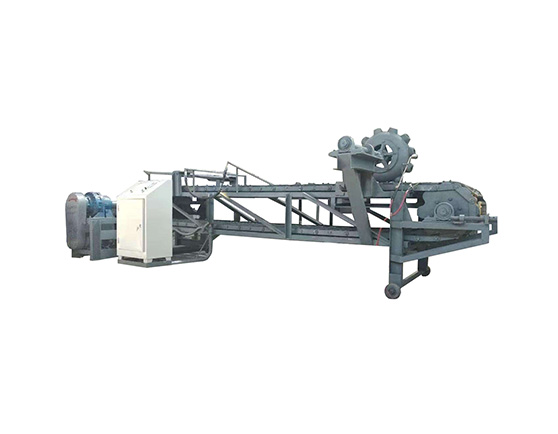

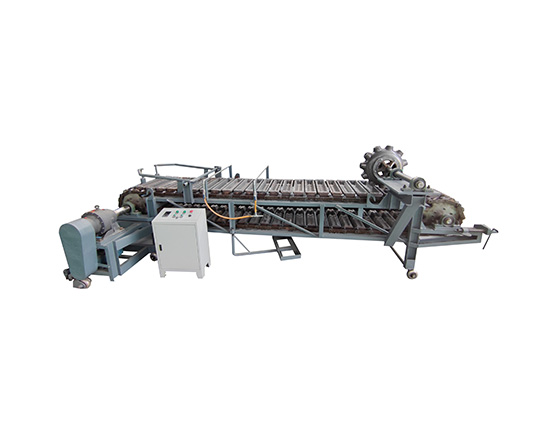

Continuous ingot casting machine can cast aluminum ingot, copper ingot, lead ingot, magnesium ingot, zinc ingot, tin ingot , etc.

| Item/Product | Al Ingot | Mg Ingot | Copper Ingot | Zinc Ingot |

| Ingot weight | 5.5kg,7kg | 7.5kg,25kg | 10kg,18kg,20kg,25kg customized | |

| Gas protect | / | Yes | / | / |

| Running speed | 0-- 3.04 m/min | |||

| Motor power | 4Kw,5.5Kw,7.5Kw and ect. according to output | |||

| Nos. of molds | 55pcs, 70 pcs,100 pcs, 130 pcs… according to output | |||

| Output per hour | 300kg-25T, customized | |||

| Pouring type | Automatic liquid distributor | |||

| Cooling type | Water spray ingot cooling, Mold bottom cooling, natural cooling | |||

| Demoulding | Knock-out hammer | |||

1.Easy operation: Easy to operate & install with good cooling effect.

2.Stable operation: 24-hour continuous casting.

3.Longer service life.

4.Adjustable water valves: 100% demoulding rate.

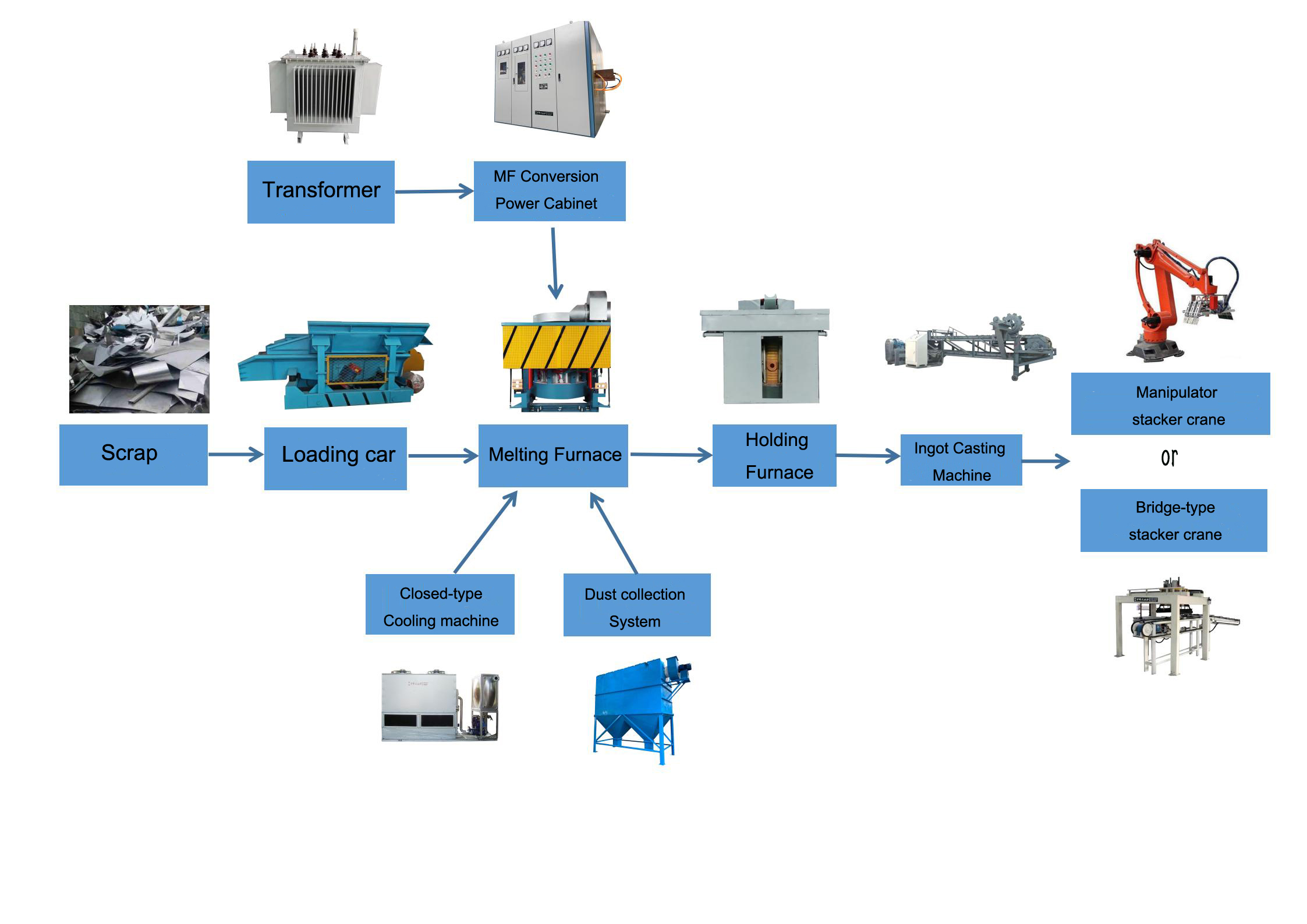

Part 1: Metal scrap.

Part 2: Induction melting furnace – metal liquid

Part 3: Holding furnace – storing metal liquid

Part 4: Ingot casting machine – metal ingot

Part 5: Ingot stacking machine or mechanical arm – ingot stacking

Part 6: Packaging

1.Intelligent operation management.

2.easy operating.

3.reduce labor force,reduce labor intensity.

4.Stacking mode is convenient and simple to adjust, and can be operated on the touch screen.

5.Several types of stacking can be done without changing the stacking parts.

6.Imported components, reliable quality and performance.

7.Using touch screen operation to realize man-machine dialogue, can display production speed, fault cause and location, high degree of automation.

8.It can not only provide the stacking efficiency of enterprises, but also improve the production and sales efficiency of enterprise.

Don’t hesitate to fill in the form & we will reply to you as soon as possible!