- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

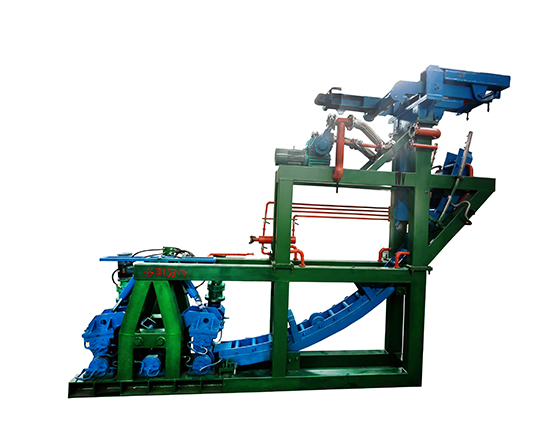

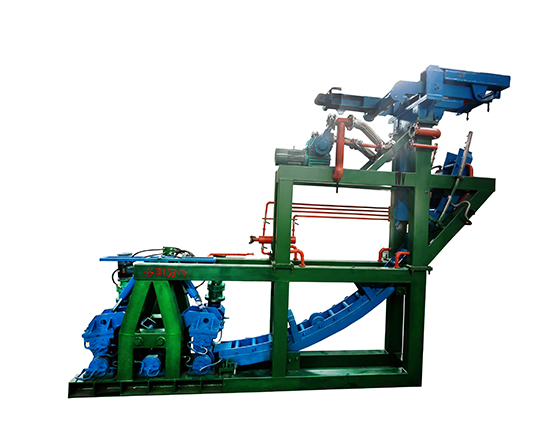

Application:

The continuous casting machine (CCM) is generally used in billets making and rolling mill production line.

According to the billets size, the R2.5-R6.0M radians are possible to choose.

According to the output, single strand, two strands to 7 strands are available for customized steel foundry production line.

As for the small billets size and output, we produced a brief integrated CCM which is more easy to install and place. Your customized CCM is welcomed!

|

CCM Radius (m) |

Fitted Billet Size (mm) |

Square billet Single strand output (Ton/Hour) |

Round billet Single strand output (Ton/Hour) |

| R3.5 | 60x 60 | 4 | |

| 70x 70/Φ70 | 6.5 | 4 | |

| R4.0 | 80x 80/Φ80 | 8.5 | 6.5 |

| 90x 90/Φ90 | 9 | 7.5 | |

| 100x 100/Φ100 | 10 | 9.5 | |

| R5.25 | 90x 90/Φ90 | 10 | 9.5 |

| 100x 100/Φ100 | 14 | 11 | |

| 120x 120/Φ120 | 17.5 | 12.5 | |

| R6 | 120x 120/Φ120 | 19 | 14 |

| 130x 130/Φ130 | 22.3 | ||

| 150x 150/Φ150 | 29.7 | ||

| 160x 160/Φ160 | 33.8 |

Don’t hesitate to fill in the form & we will reply to you as soon as possible!