- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

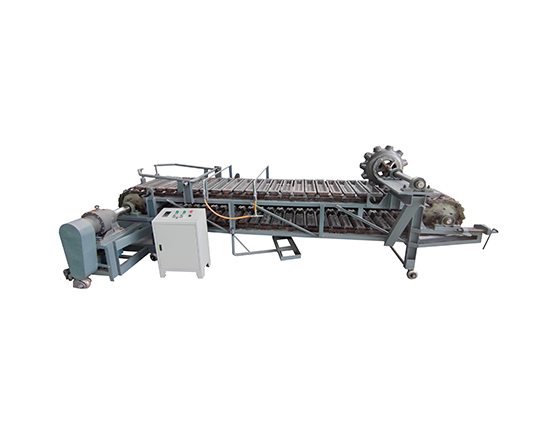

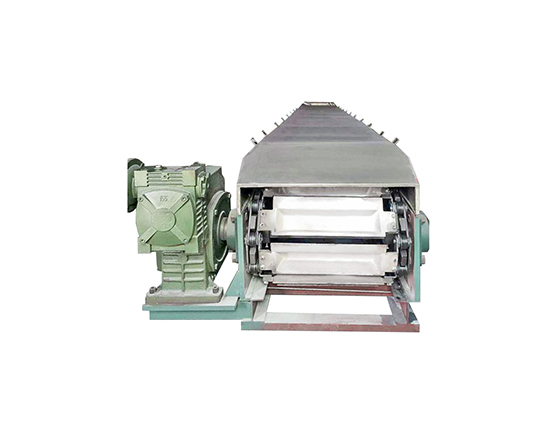

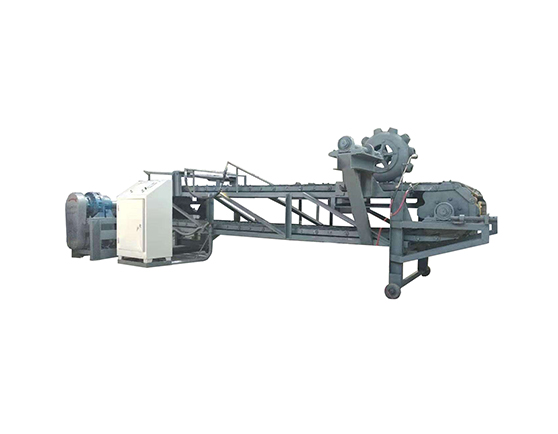

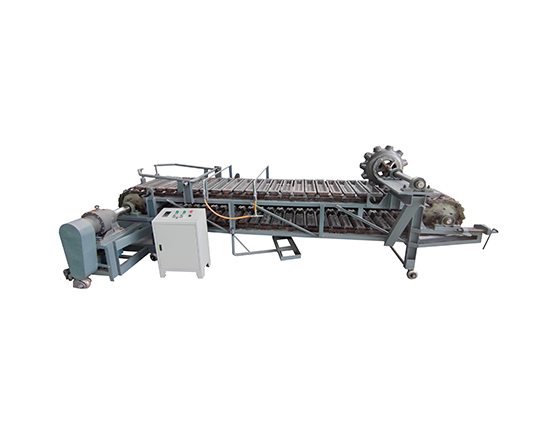

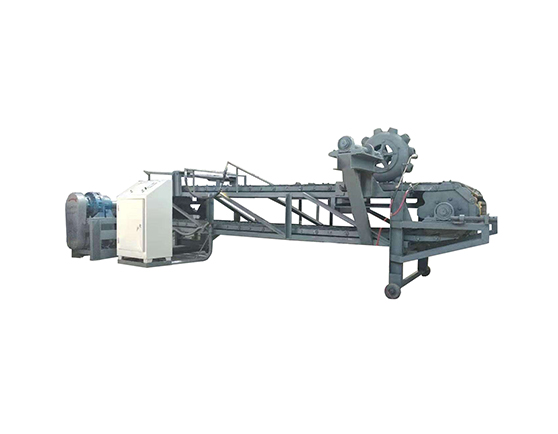

Application:

used for casting copper ingot,aluminum ingot,magnesium ingot,zinc ingot ,etc.

| Item/Product | Al Ingot | Mg Ingot | Copper Ingot | Zinc Ingot |

| Ingot weight | 5.5kg,7kg | 7.5kg,25kg | 10kg,18kg,20kg,25kg customized | |

| Gas protect | / | Yes | / | / |

| Running speed | 0-- 3.04 m/min | |||

| Motor power | 4Kw,5.5Kw,7.5Kw and ect. according to output | |||

| Nos. of molds | 55pcs, 70 pcs,100 pcs, 130 pcs… according to output | |||

| Output per hour | 300kg-25T, customized | |||

| Pouring type | Automatic liquid distributor | |||

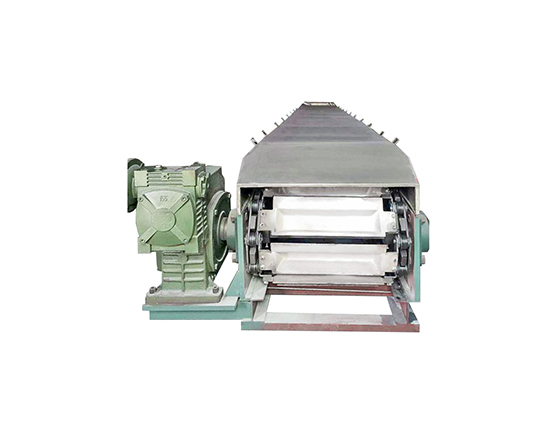

| Cooling type | Water spray ingot cooling, Mold bottom cooling, natural cooling | |||

| Demoulding | Knock-out hammer | |||

1.Easy operation: Easy to operate & install with good cooling effect.

2.Stable operation: 24-hour continuous casting.

3.Longer service life.

4.Adjustable water valves: 100% demoulding rate.

Don’t hesitate to fill in the form & we will reply to you as soon as possible!