China Kunming copper wire production line

- Project: copper wire production line

- Final Products: Purity 96% copper wire

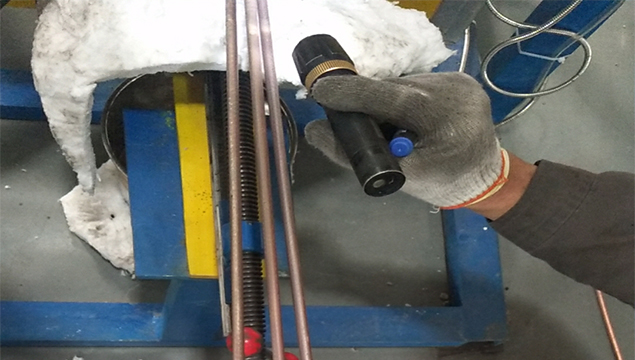

- Production Equipment: Horizontal continuous casting machine; cooling machine; resistance vacuum annealing furnace

- Production Capacity: 90 KG/Hour

- Brief introduction:

This project is making the copper wire of mobile phone charging cable. The material is copper silver alloy and the copper purity is 96%.

The core is an important carrier for data transmission and charging in the data line, and its quantity and thickness are also different. Bare copper refers to pure copper conductor in the industry. Bare copper refers to copper wire drawn from pure copper rod. Its surface is not subject to any coating processing. The material is single, and the surface and interior are all copper metal, with a yellow appearance. Bare copper wire is soft, and is commonly used for processing pure copper conductor. It has good conductivity and strong signal transmission stability.

The density of copper wire is 8.89g/cm3, it has good electrical conductivity, the conductivity is second only to silver, the purer the copper, the better the conductivity; Good thermal conductivity, second only to silver and gold; It also has certain mechanical strength, good corrosion resistance, no low temperature brittleness, easy to weld, strong plasticity, easy to withstand all kinds of cold and hot pressure processing.

For the products with good electrical conductivity requires oxygen free copper wire. It’s different with horizontal continuous casting line. Only upward continuous casting line can fit this process requirement.

- Production line component: Horizontal continuous casting machine; cooling machine; straightening machine; rolling mill; resistance vacuum annealing furnace

- Production process: producing copper rod — vacuum annealing — straightening — rolling to copper wire — finishing