- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

Application:

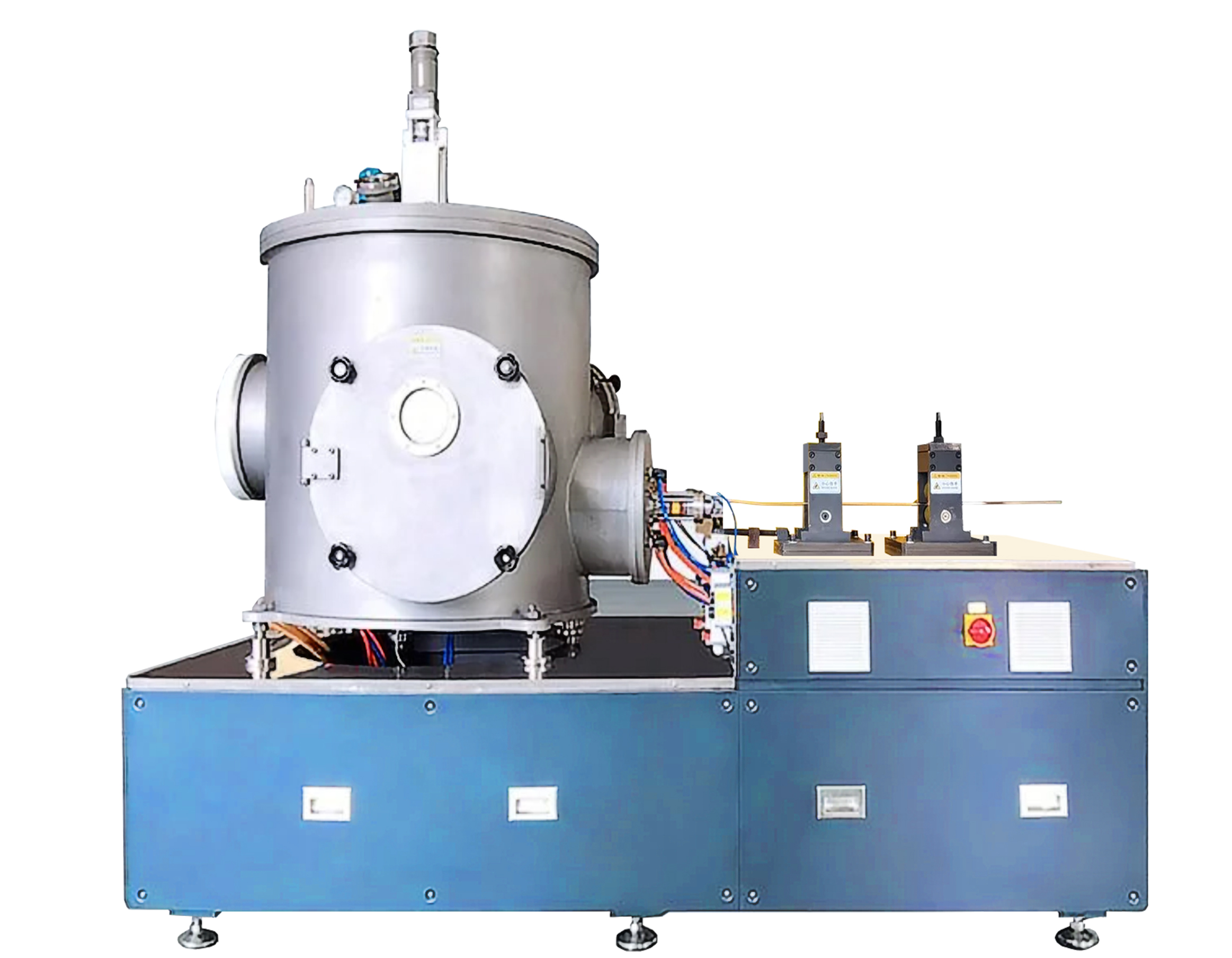

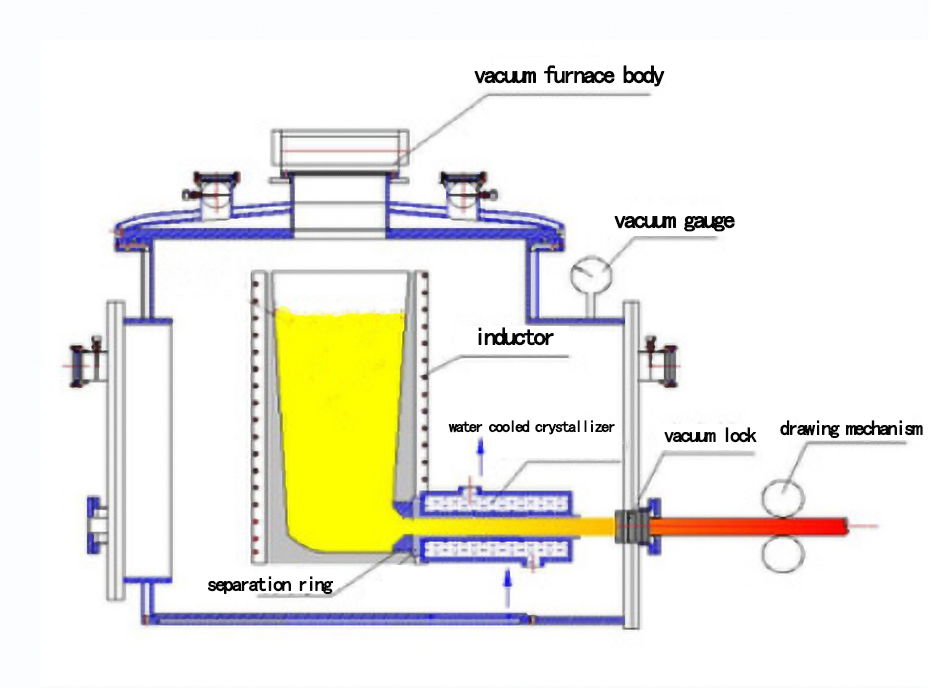

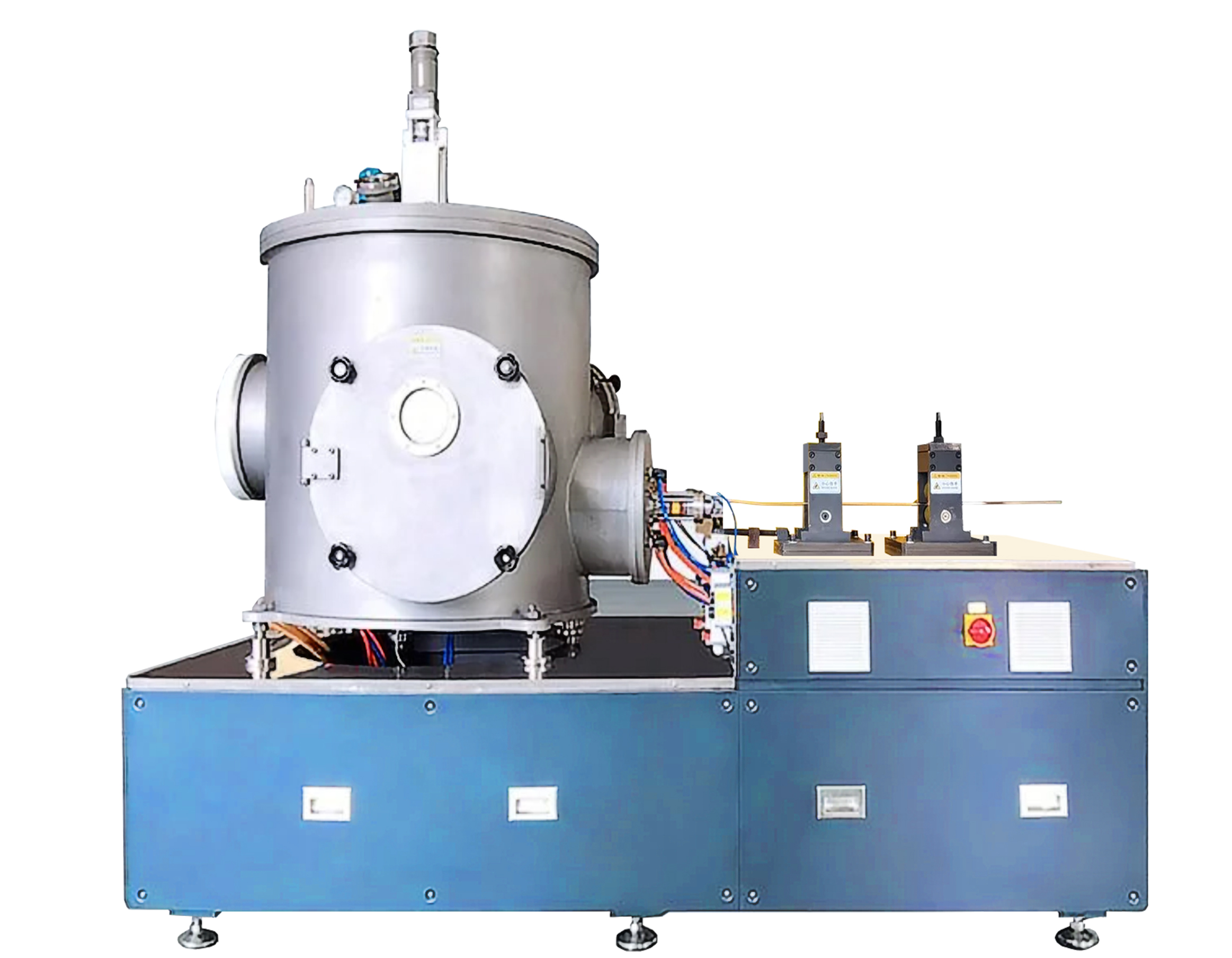

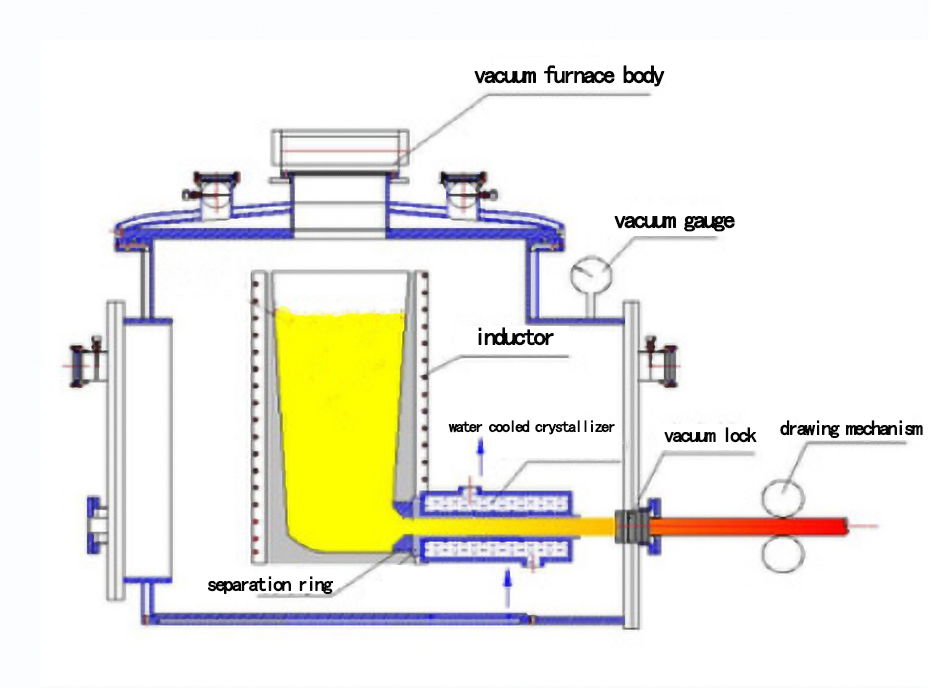

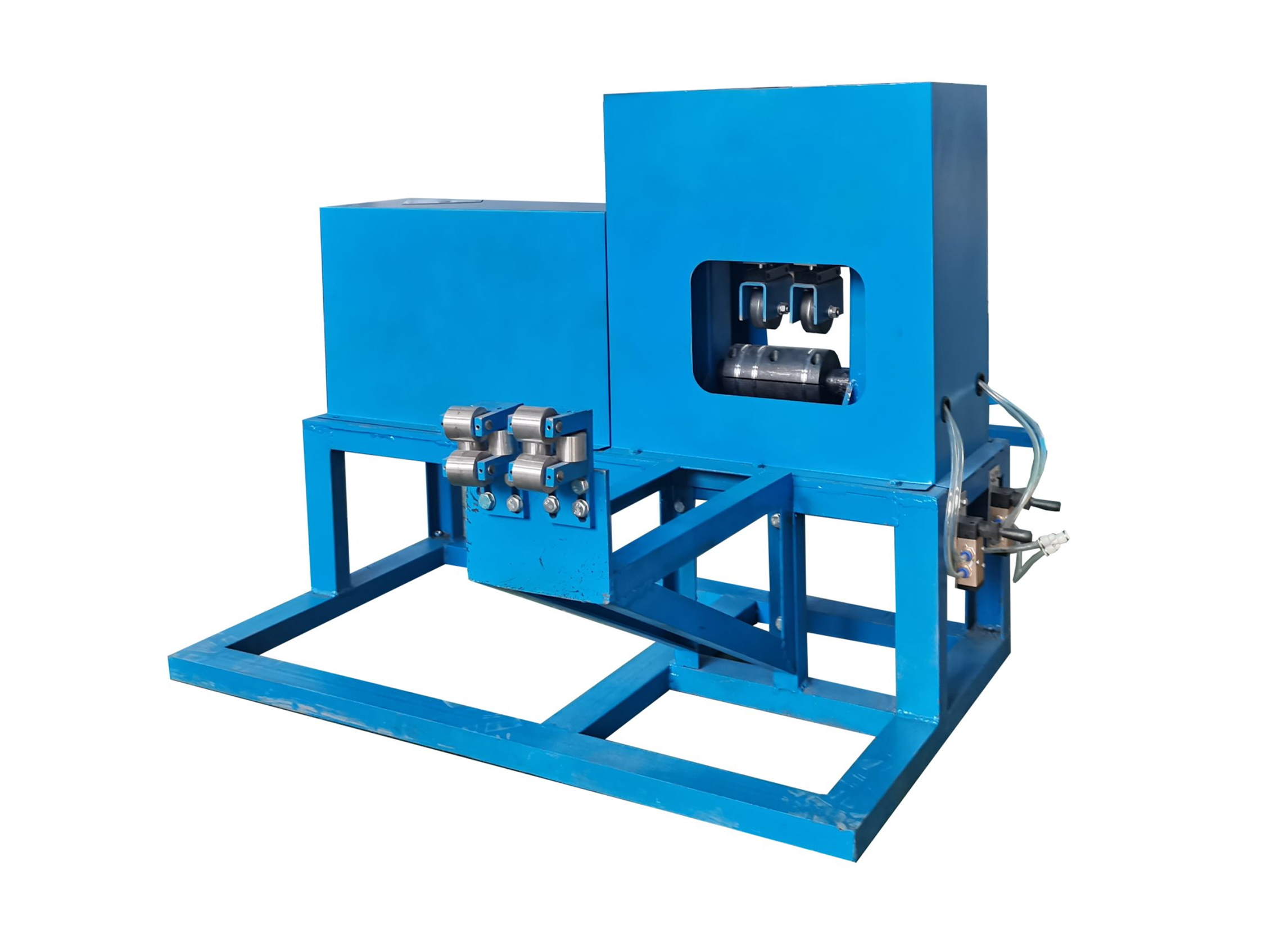

The vacuum continuous casting machine uses the principle of medium frequency induction heating to melt metal or metal alloy under vacuum condition. Modern molding equipment for drawing and casting metals and alloys through crystallizer cooling (sheets, plates, tubes) through a specially designed ingot drawing mechanism. This set of super-alloy vacuum horizontal continuous casting integrated technology and complete equipment can carry out super-alloy smelting and continuous casting in vacuum environment, and realize high-quality continuous casting molding of super-alloy family. It is suitable for high quality pure purification production of high content super-alloys such as high titanium, high nickel, single crystal copper, etc. It is the best technical way to produce low cost and high quality super-alloy master alloy and high quality electrode rod, and can prepare high purity, low segregation, dense structure and arbitrary length super-alloy base metal.

Don’t hesitate to fill in the form & we will reply to you as soon as possible!